PMM-G measuring machine made by Leitz

The development of measurement technology in recent years and decades is still exciting to follow today. In the beginning, simple measuring methods using measuring plates, measuring tables and test benches were sufficient, but over time the demands on product quality and process reliability have increased. Measurement accuracies resulted from the basic geometry of the plates used and the measurement uncertainty of the respective probes. However, measuring tasks became increasingly complex and dynamic, and results had to become more precise. This heralded the dawn of spatial coordinate metrology.

Accuracy means minimising deviations

3D coordinate measuring machines consist of a positioning system, a high-resolution measuring system, switching or measuring sensors, an evaluation system and measuring software. To achieve high measuring accuracies, the measuring deviations must be minimised.

Measurement errors are differences between the value displayed by the measuring instrument and the actual reference value of a geometric quantity (calibration standard). Modern coordinate measuring machines (CMMs) achieve a length measurement error E0 of 0.3+L/1000 µm (L is the length to be measured). The length measurement deviation is significantly influenced by the design of the measuring device, the probe, the measuring strategy, the workpiece and the user. The mechanical design is the factor that is best and most sustainable to influence.

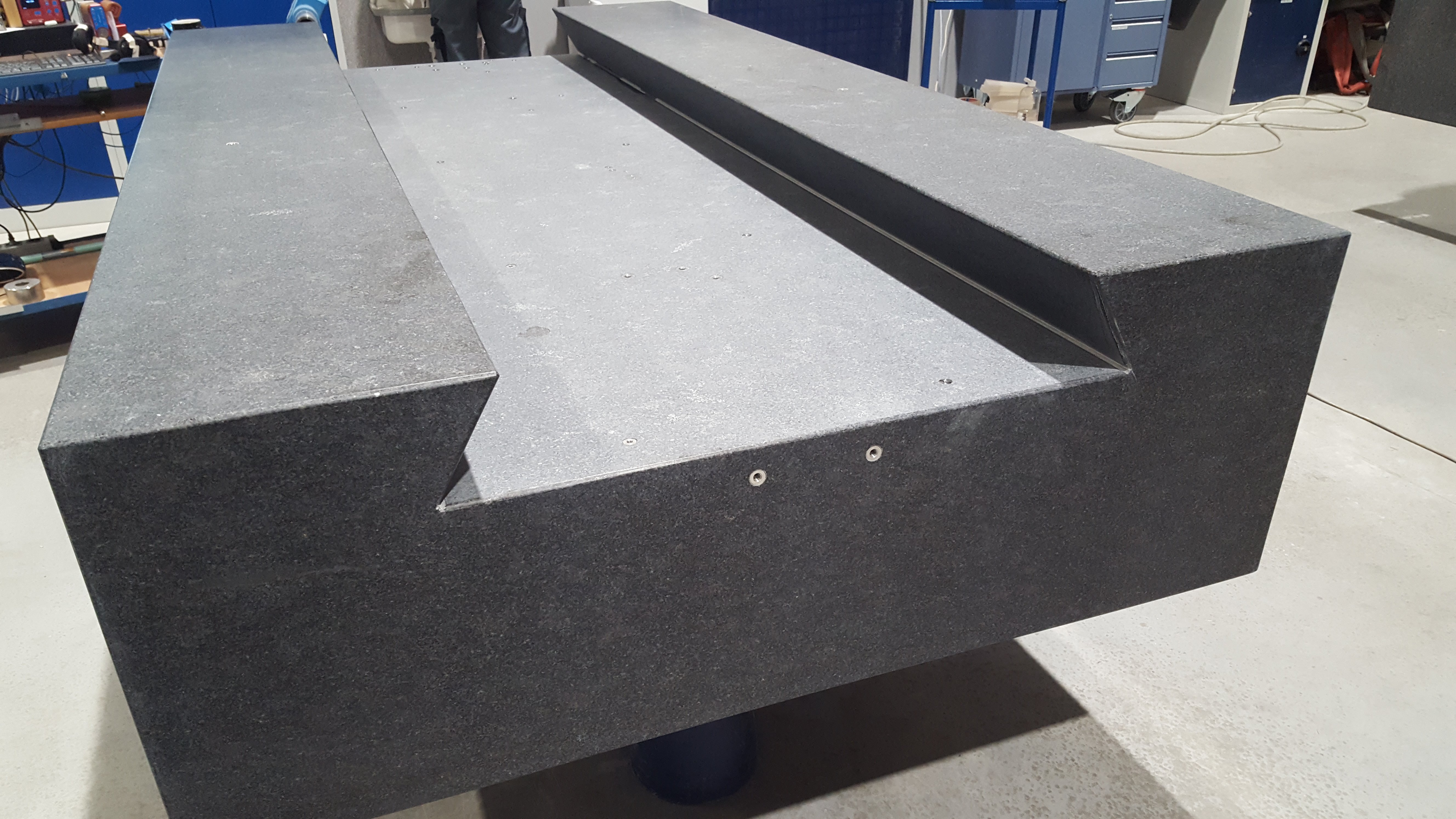

Air bearing guide of a measuring machine – flatness < 6µm and flatness < 2µm / 110 x 110 mm

The use of granite in metrology is one such factor to influence the design of CMMs. Granite is an excellent material for modern requirements because it meets four requirements that make the result more accurate:

1. High inherent stability

- Granite is a volcanic deep rock comprising the three main components quartz, feldspar and mica, formed by crystallisation of rock melts in the earth's crust.

- "Aged" over several thousand years, granite is homogeneous and free of internal stresses. Impala, for example, is about 1.4 million years old.

- Granite has a great hardness: Mohs' hardness 6 on a hardness scale up to 10.

2. High temperature resistance

- Compared to metallic materials, granite has a lower coefficient of expansion (approx. 5 µm/m*K) and thus a lower absolute expansion compared to these materials (e.g. steel α = 12 µm/m*K).

- The lower thermal conductivity of granite (3 W/m*K) compared to steel (42-50 W/m*K) ensures a slower reaction to temperature fluctuations.

3. Very good vibration damping

- Due to its homogeneous structure, granite is free of residual stresses. This reduces vibrations.

4. High accuracy of the CMM guides

- The use of granite as a measuring plate made of natural hard stone enables very good machining with diamond tools so that machine components are manufactured with high basic accuracies.

- By manual lapping, the accuracy of the guides is optimized according to the requirements to the micron.

- During lapping, load-related deformations of the components can be taken into account.

- This results in highly-compressed surfaces which allow the use of air bearing guides. Air bearing guides are highly accurate due to the high surface quality and contactless movement of the axes.