Machine construction increasingly using mineral casting for machine beds

Industry awareness of environmental compatibility, carbon emissions and the energy balance in production has boosted the interest in alternative mineral raw materials. Mineral materials are being used instead of steel for the machine beds in mechanical and plant engineering. The mineral alternative to steel has a number of advantages in almost every aspect of sustainability and environmental compatibility, the main one being the significantly lower energy consumption required for its production.

13.5m long linear axis made of granite before machining

Ultimately, though, the key factors in the choice of mineral machine beds are the outstanding physical properties with regard to temperature behaviour, geometric stability and vibration damping. These properties are quite literally the foundation of any machine where geometric precision is important.

With regard to mineral building materials, there are several that are suitable. In addition to the natural resource of hard natural rock (mainly granite from South Africa and Europe), mineral casting is a highly advantageous and extremely versatile solution for machine components, and especially for machine beds.

Types of mineral casting for machine components

There are two groups of mineral casting:

- epoxy resin bound mineral casting, which is referred to colloquially as mineral composite or polymer concrete, and

- cement bound mineral casting, also known as concrete mineral casting, ultra high performance concrete (UHPC) or high-strength concrete.

As granite is highly suitable for precision machine construction, it has been used for decades as a material in testing and measuring technology and in machine tool construction. So granite became the forerunner for mineral casting, which has similar product properties to granite.

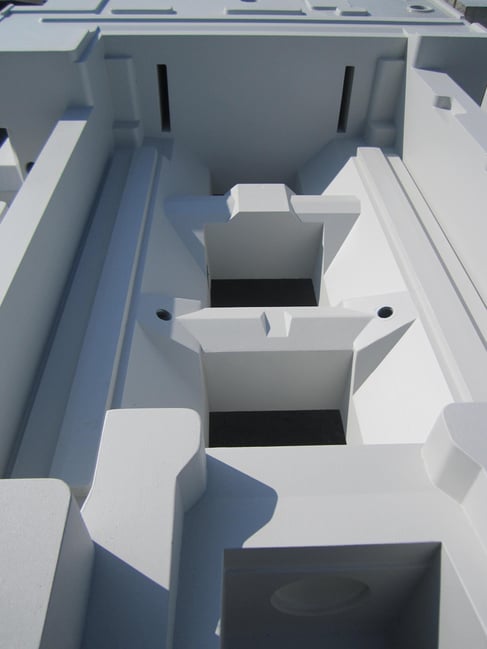

Casting from UHPC: mineral casting bed with openings for chip removal before machining the guide rails

Advantages of using mineral casting for machine beds

As with grey cast iron, there are two key factors to consider when using mineral casting:

- the component costs when producing large quantities, and

- the many different options for the design of the component, and in particular the processing of functional elements such as temperature control, hydraulic lines, empty pipes or sensors.

Granite components are mechanically processed from a monoblock. This has advantages for the geometric stability. The disadvantage is that the design options are more limited than with mineral casting, which is why the requirements need to be balanced against the choice of material at the design stage.

A machine bed or machine component made of mineral casting is cast in moulds. And although this reduces the mechanical processing to machining the accuracy surfaces, it also comes with higher initial costs for the casting mould. However, they are very quickly offset if a higher number of units is produced of the machine or plant in question. With mineral casting, functional elements such as hydraulic lines or sensors can be incorporated during construction.

The future belongs to machine beds made of granite and mineral casting

Machine and plant manufacturers are well advised to involve experts in the field of mineral-safe materials from the development phase and jointly weigh up all the details of every aspect with regard to accuracy requirements and cost-effectiveness. Even hybrid constructions in steel and mineral casting can often be a perfect solution.

The experts at Reitz Natursteintechnik have decades of experience in the use of mineral casting (both polymer concrete and UHPC) and granite in machine and plant engineering. Their expertise in this field can contribute greatly to the success of a machine or plant.