Opportunities for 3D printing mineral materials

The 3D printing process is becoming increasingly important. The key difference over the tried-and-tested production processes of sawing, turning, milling, drilling and grinding is that an item is not created by machining it from a blank, but by modelling material into an item in various printing processes. In machining processes, this leaves us with chips as material loss. 3D printing processes have a much better track record in terms of "material loss and waste". In 3D printing, a number of machining processes can be mapped at the same time. In addition, complex shapes with undercuts are possible, which is not the case in machining processes.

While 3D printers were initially an excellent instrument for producing prototypes and single items, they are becoming increasingly important for series products with a wide range of varieties. While the first 3D print products were basic parts of fairly low accuracy, 3D printing processes are becoming more and more accurate, and offer opportunities for the production of precision parts.

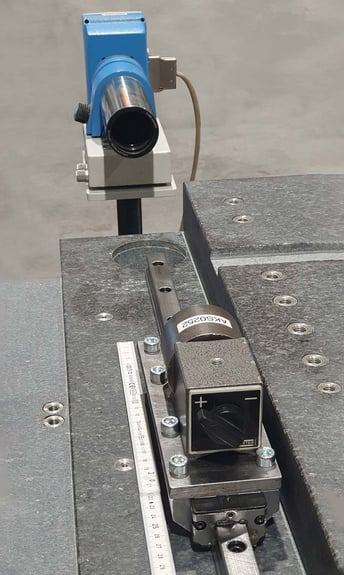

Fig. 1: Measuring the straightness of the mounted reference guide rail in the µ range

Accuracy, precision and tolerance

A number of additional factors need to be taken into account with 3D printing for component accuracy. Accuracies depend on the material, its mechanical properties, and the type of components. Layer-by-layer construction may have implications for inaccuracies.

A number of additional factors need to be taken into account with 3D printing for component accuracy. Accuracies depend on the material, its mechanical properties, and the type of components. Layer-by-layer construction may have implications for inaccuracies.

Factors that influence component accuracy are:

- the printing process

- material

- resolution

- Mechanical accuracy and repeatability

The accuracy of 3D printing processes is greatly limited by the projected pixel size (also called XY resolution).

So in order to achieve high accuracies, it is especially important that the frames of 3D printers have a high accuracy and repeatability in the 3 printing axles. This is the only way to achieve the smallest possible variation due to pixel size.

As 3D printing technologies are also subject to temperature fluctuations, the advantageous physical-thermodynamic properties of mineral materials such as granite or UHPC (concrete) make them ideal for frames in 3D printing processes.

The benefits of granite frames:

- low thermal expansion

- low thermal conductivity

- very good vibration damping

- very good resistance to chemicals

- not magnetic

- not electrically conductive

Granite is therefore a perfect material for the construction of precision 3D printing machines. The use of granite components in frame construction will help to increase precision in this pioneering production process.

Fig. 2: Measuring the area for the guide system for straightness and rotation errors in the µ range

We look forward to supporting you in the use of mineral materials such as granite and UHPC.