Granite & concrete vs. steel in mechanical engineering: five convincing properties

Mineral materials such as natural hard stone (granite) or high-strength concrete UHPC (Ultra High-Performance Concrete) are becoming increasingly important in mechanical and plant engineering. Their properties make them a convincing alternative to conventional steel and cast iron constructions.

There are a number of reasons for using the natural materials of concrete and granite. First and foremost: their excellent physical properties, the high precision of the machine components and a very good environmental footprint.

Machine and plant manufacturers are increasingly recognising these advantages and are thus creating competitive advantages. There are sound arguments for this:

Comparison 1: Thermal properties of concrete and granite vs. steel/cast iron

The thermal properties of the frame materials have a significant influence on changes in geometry and thus on the accuracy of the machine components. The facts for comparison:

Thermal properties at 20 °C steel/cast iron, concrete and granite in comparison

| Linear expansion coefficients - α (10-6/K) | Thermal conductivity λ (W/(m*K)) |

Specific heat capacity cp - J/(kg * K) |

|

| Steel | 11.1 – 11.5*** | 46 – 50* | 490 – 502** |

| Grey cast iron | 10 – 11.7**** | 45.5 – 52.5**** | 460 – 540 ** |

| UHPC (MBB-50) | 10.8 – 11.2 | 1.8 – 2.4 | 900 |

| Granite |

5 – 7.5 |

3 | 845 |

*Source | **Source | ***Source | ****Source

As can be seen from the table, from a thermal point of view, mineral materials are much better materials for precision machine components than materials such as steel and grey cast iron. Granite has the absolutely lowest coefficient of linear expansion of the compared materials and changes the least in terms of absolute linear expansion.

Due to their low thermal conductivity and higher specific heat capacity, granite and high-strength concrete UHPC react much more slowly to temperature changes than metallic materials. Especially short-term and higher temperature differences lead to permanent changes in the geometry of steel and grey cast iron.

Comparison 2: Vibration damping of concrete and granite vs. steel/cast iron

Natural oscillations and external vibrations have undesirable effects on processing machines such as

- Negative influence on machining accuracy (position)

- Deterioration of the surface quality (roughness)

- Higher tool wear

Material damping in comparison

| Damping in 10³ kg/ms | |

| Steel | 0.002* |

| Grey cast iron | 0.003* |

| UHPC (MBB-50) | 0.03 |

| Granite | 0.03 – 0.04 |

*Source: Verlag Moderne Industrie; Die Bibliothek der Technik; volume 231

The vibration behaviour of mineral materials compared to metallic materials (steel and grey cast iron) is characterised by a lower natural frequency and a faster reduction of the vibration amplitude during vibration transmission. Noise pollution is also becoming increasingly important, which is much lower in granite and concrete than in steel structures due to their better properties.

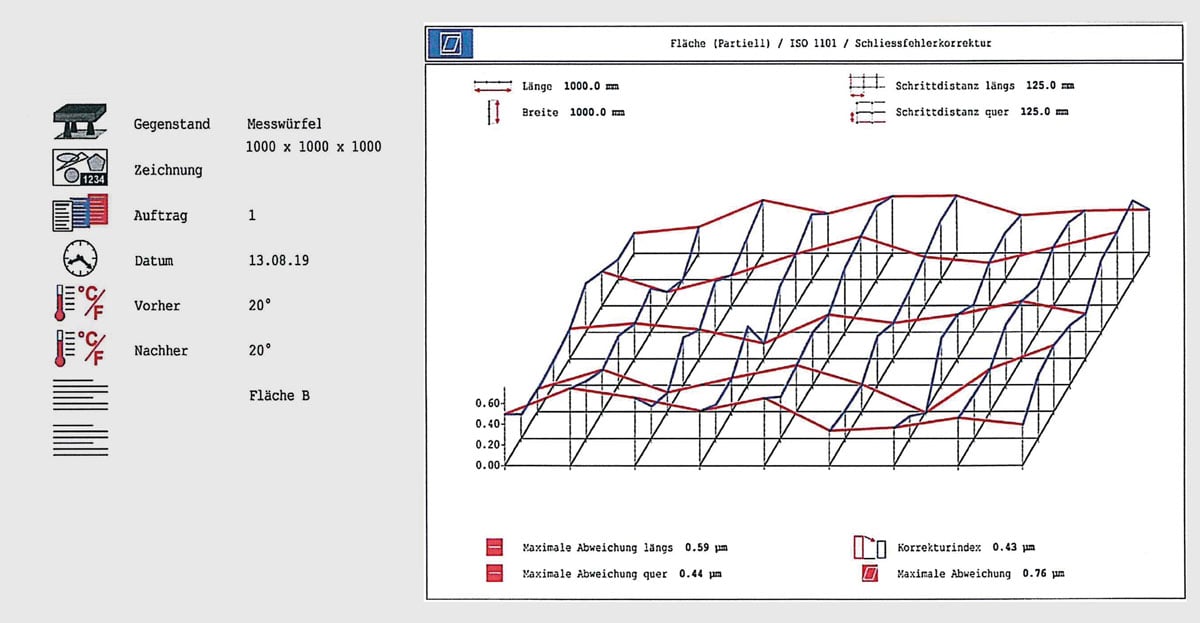

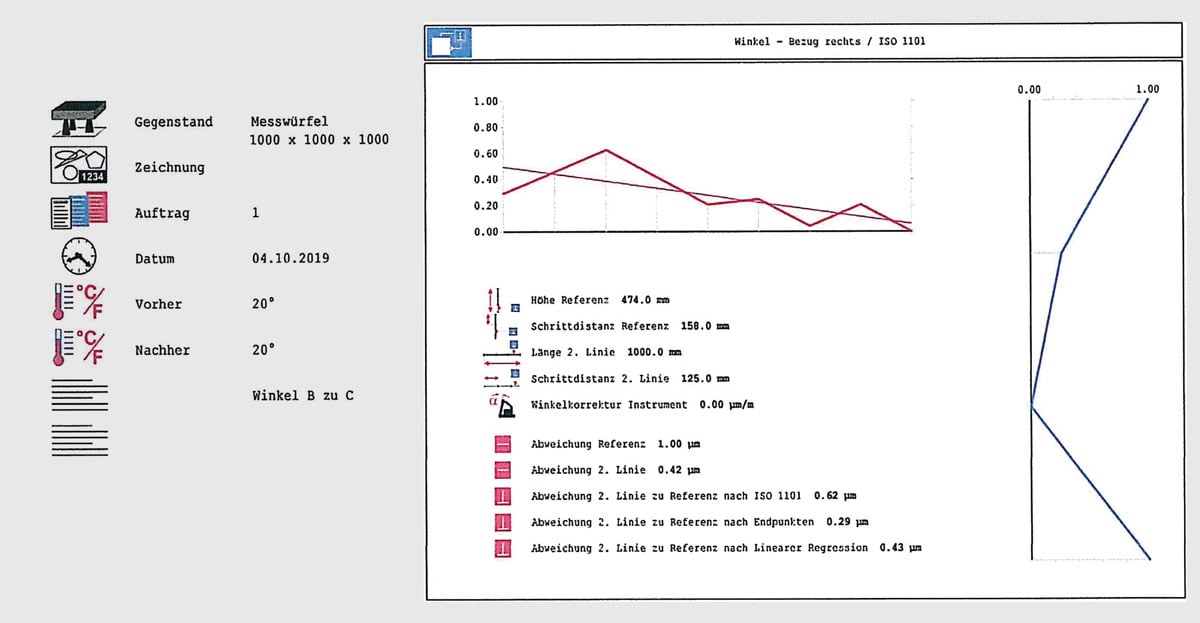

Application example: measuring cube

Results of the precision test:

Comparison 3: Concrete and granite are stress-free, steel/cast iron are not

Metallic and mineral materials differ from each other due to their production or formation.

Steel and cast steel/grey cast iron are melted down and cast at high temperatures. Cooling causes stresses in the material. These can then be reduced during further processing by energy-intensive processes. Residual stresses remain.

UHPC components (concrete) are cast in a self-compacting manner. The material compacts without mechanical effects and without stress due to the precisely adjusted grading curve in combination with superplasticizers.

Granite is a deep rock, formed from magma within the earth's crust. It has "matured" for millions of years so tensions in the material are completely relieved.

Comparison 4: High end precision machining of concrete and granite vs. steel/cast iron

Granite and UHPC concrete can be machined with the same mechanical precision as steel and grey cast iron. Due to the lack of material stresses and the lower density compared to steel and cast iron, higher accuracies are achieved by manual lapping for granite and UHPC.

Comparison 5: Energy and CO2 footprint of concrete and granite vs. steel/cast iron

Steel and cast iron components:

- High expenditure due to excavation of raw materials in mines

- Very high expenditure due to melting process for steel and grey cast iron: temperature-intensive process

- Recyclable through melting, high expenditure

UHPC-components:

- Average expenditure for excavating minerals in gravel pits

- Average expenditure for production of cement

- Low expenditure for mixing and casting process MBB-50: no heating necessary

- Recyclable by shredding and use as material for road construction, low expenditure

Granite components:

- Low energy consumption when quarrying the granite blocks in the quarry

- Recyclable by shredding and use as material for road construction, low expenditure